cosmetic cream vacuum emulsifying mixer

$20,000.00

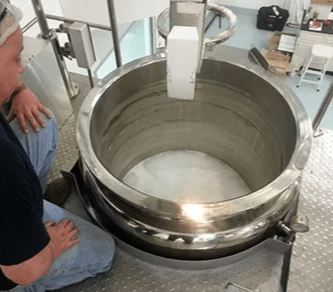

1. The whole vacuum emulsifying mixer has three pots: the main/emulsifying pot , the water pot , the oil pot .Water and chemical raw material are first put into the water pot and oil pot, preheated and premixed there.Then they will be sucked into the main pot through a connected pipeline. Product are finally heated and mixed in the main pot.

2. The whole lid of the main pot is lifted by hydraulic system. On the top of the lid, there is the vacuum gauge, vacuum sucking inlet, fragrance adding hopper, vauum breaker, sight glass and light.

3. The main pot has two mixing ways: the upper scraper mixing and the bottom homogenizer mixing

(1). upper scraper mixing: Motor: Siemens

Rotational Speed: 0-63rpm (Taiwan Delta frequency changer )

(2). bottom homogenizer mixing: Motor: Siemens

Rotational Speed: 0-3500rpm (Taiwan Delta frequency changer speed control)

All material-contact parts adopts the stainless steel 316L.

4. Control Panel: three pots are all with electric heating. The machine adopts the Omron temperature controller, Delixi digital control. Siemens motor and Taiwan Delta frequency changer.

Application : This cream vacuum emulsifying mixer is to mix or produce the cosmetic cream products such as facial mask, hand cream, day cream, facial cleanser, sun screen cream, skin whitening products, etc. Its main function is to give good fineness product and balance the oil phase and water phase.

This vacuum emulsifying mixer is qualified for GMP manufacturing, and so it is also used to produce ointment in the pharmaceutical industry. Cosmetic products are actually the mixture of the water and chemical raw material in proper according to special proportion. When they are well mixed, we get the final product. The rest work is packing (including the filling, capping, labeling, printing, etc). So the producing is the mixing.